Diecasting is a highly specialized production process that transforms the melts of metal into precisely-defined components using high-pressure molds. This technique has become indispensable for a wide range of industries such as electronics, aerospace, automotive as well as consumer products, because it can produce complex shapes with exceptional precision and consistency. By combining the principles of metals with modern engineering it provides unparalleled effectiveness and precision. This makes it a fundamental element of modern manufacturing. This article explores the complicated world of diecasting, exploring its process, advantages in a variety of ways.

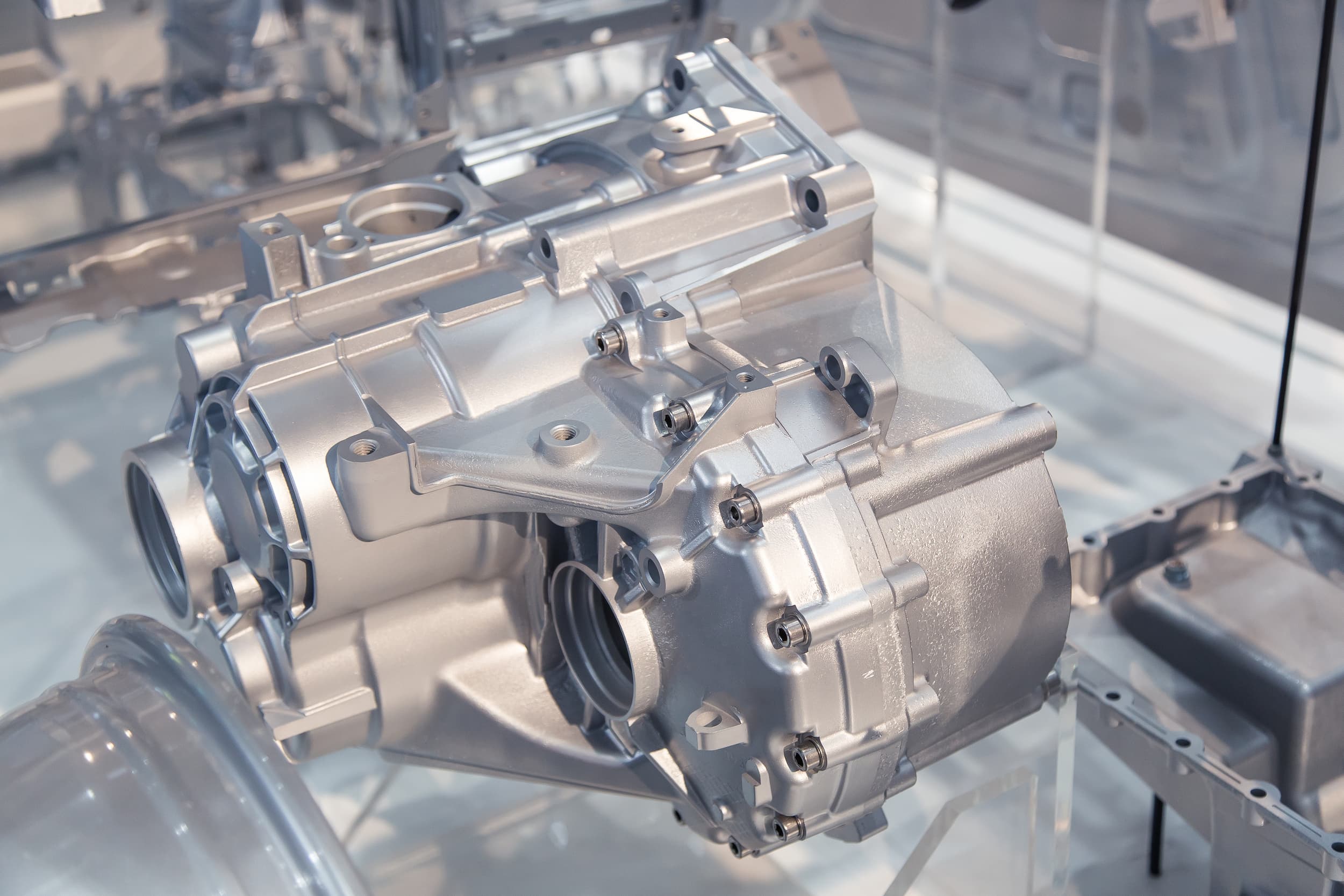

The diecasting process begins with the preparation of high-quality steel molds, known as dies. These molds are created to withstand the intense pressures as well as the high temperatures produced by molten steel. These dies are meticulously crafted to take in intricate details and ensure tight tolerances making sure that every part cast conforms to specific specifications for design. In the process of casting, metals like aluminum, magnesium, zinc, as well as copper are heated and in the cavity of the die at high pressures. Rapid injections and cooling result in parts which have excellent dimensional stability and a smooth top finish. The high precision of dies allows for the creation of components with complex geometries, which are often unattainable by other methods of manufacturing.

One of the major benefits of diecasting is the efficiency in mass production. When dies are manufactured it can be repeated hundreds or thousands instances with very little variation between pieces. This high repeatability is crucial for businesses that require huge volumes of identical components. Diecasting is also known as an efficient material. It produces lower waste than different metal-forming methods because excess metal can be recycled and used again. This not only reduces cost of materials but it helps to promote more sustainable manufacturing practices. A combination of accuracy, speed and material efficiency makes diecasting a desirable choice for production in high volumes.

Diecasting has numerous advantages regarding mechanical properties. Parts made through diecasting generally have excellent durability and strength due to the fine grain structures that are formed from the swift cooling of molten metal. This makes diecast parts perfect for use in applications that require high performance and reliability. In addition, the process allows for the incorporation of thin walls and complex elements but without degrading their structural strength. This is especially beneficial for aerospace and automotive industries where weight reduction and retaining strength is crucial. The ability to produce robust, lightweight components can improve the efficiency of fuel and performance in vehicles and aircraft. To obtain further information please check out www.senadiecasting.com.my/

Diecasting's flexibility extends beyond the mechanical advantages to its flexibility in a variety of applications. In the field of electronics, diecasting can be employed to manufacture enclosures, heat sinks, and connectors, ensuring that devices are protected and function efficiently. The process is also widely employed in the production of everyday consumer items, including household appliances to power tools, where high-quality and long-lasting are the most important factors. Diecasting is a process that can produce detailed and complicated parts can make diecasting a desirable option for engineers and designers who want to improve and innovate product performance. In allowing a variety of different metals and the incorporation of complex features that diecasting allows the design of innovative products in a variety of different industries.

Diecasting is a vital manufacturing method that permits the manufacturing of precision high-quality metal parts across an array of different industries. Its capacity to design complex shapes with tight tolerances, smooth surfaces is essential for projects that require intricate detail and constant quality. The efficiency and cost-effectiveness of diecasting further enhance its appeal, supporting mass production while maintaining the highest quality. Technology advances, and the need for reliable strong, lightweight and robust components grows, diecasting will remain a cornerstone of modern manufacturing. It drives advancement and innovation in manufacturing.

Comments on “Diecasting: The Spine of Precision Manufacturing”